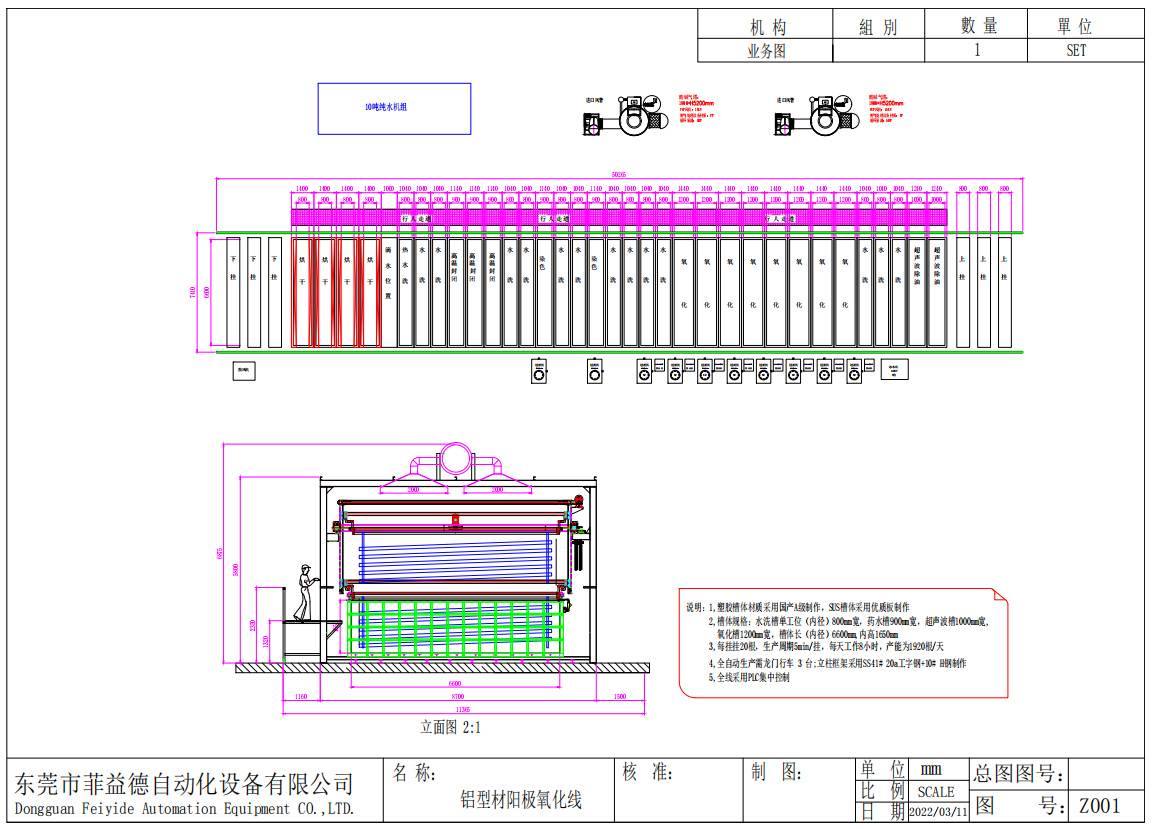

The Aluminum profile automatic oxidation production line for aluminum profiles is a highly intelligent industrial equipment designed specifically for surface oxidation treatment of aluminum profiles. Through automated equipment, it achieves continuous and efficient chemical processing of aluminum materials, with core goals including improving production efficiency, reducing manual intervention, and ensuring product quality consistency. This production line usually consists of automatic driving, automatic power supply system (such as oxidation, coloring, electrophoresis unit), automatic cross car, workpiece conveying system, electrophoresis curing furnace, and loading and unloading device, etc. It can adapt to vertical or horizontal layout to complete the entire process of aluminum profile oil removal, alkali corrosion, anodic oxidation, dyeing, sealing, and drying

Save labor costs: The fully automated production line reduces the need for manual operations through automated operations, thereby lowering labor costs.

Reduce chemical consumption: Automated production lines can precisely control process steps and cleaning time, reducing chemical consumption and lowering wastewater treatment costs.

Improving product quality: Due to the precise control of automated production lines, product quality is more stable, reducing product quality problems caused by improper human operation.

Improve production efficiency: Automated production lines do not require manual operation of walking, crossing, curing furnaces, power supply, and other links, improving overall production efficiency.

Safe and reliable: Automated production lines reduce human operation, avoid accidents caused by illegal operations, and improve production safety.

Intelligent control system

Adopting PLC (Omron/Mitsubishi) programming and human-computer interaction interface, precise control of process parameters (temperature, current density, processing time) is achieved, supporting customized process design and high degree of automation.

Real time monitoring of equipment status and product quality, increasing production efficiency by over 30%.

Key process modules

Pre treatment system: Multi tank linkage of ultrasonic oil removal, alkali corrosion, chemical polishing, etc., to ensure surface cleanliness.

Anodizing tank: Optimized sulfuric acid electrolyte concentration to 150-200g/L (optimal 160-180g/L), temperature control ± 2 ℃ error, current density 100-200A/m ², ensuring uniformity of the oxide film.

Post processing unit: Closed dyeing (pure water washing+sealing holes), hot air drying to enhance corrosion resistance and aesthetics.